CNC Controller enclosure

What is a CNC Controller?

A CNC (Computer Numerical Control) controllers job is manage and control the movements and operations of a CNC machine.

It acts as the brain of the CNC system, interpreting the G-code instructions generated by the computer and converting them into electrical signals that drive the motors and actuators on the CNC machine.

These are the key functions and responsibilities that a CNC controller has:

- Interpret G-code

- Motion Control

- Positioning

- Tool Control

- Feed Rate Control

- Error Handling

- Tool Compensation

The CNC controller is a critical component of CNC machining systems as it directly influences the accuracy, efficiency, and quality of the manufactured parts. Advanced CNC controllers may have additional features such as multi-axis control, adaptive toolpath optimization, and communication interfaces for data exchange and monitoring.

"Hobbyist" Commercial CNC Controller

"Professional" Commercial CNC Controller

My controller

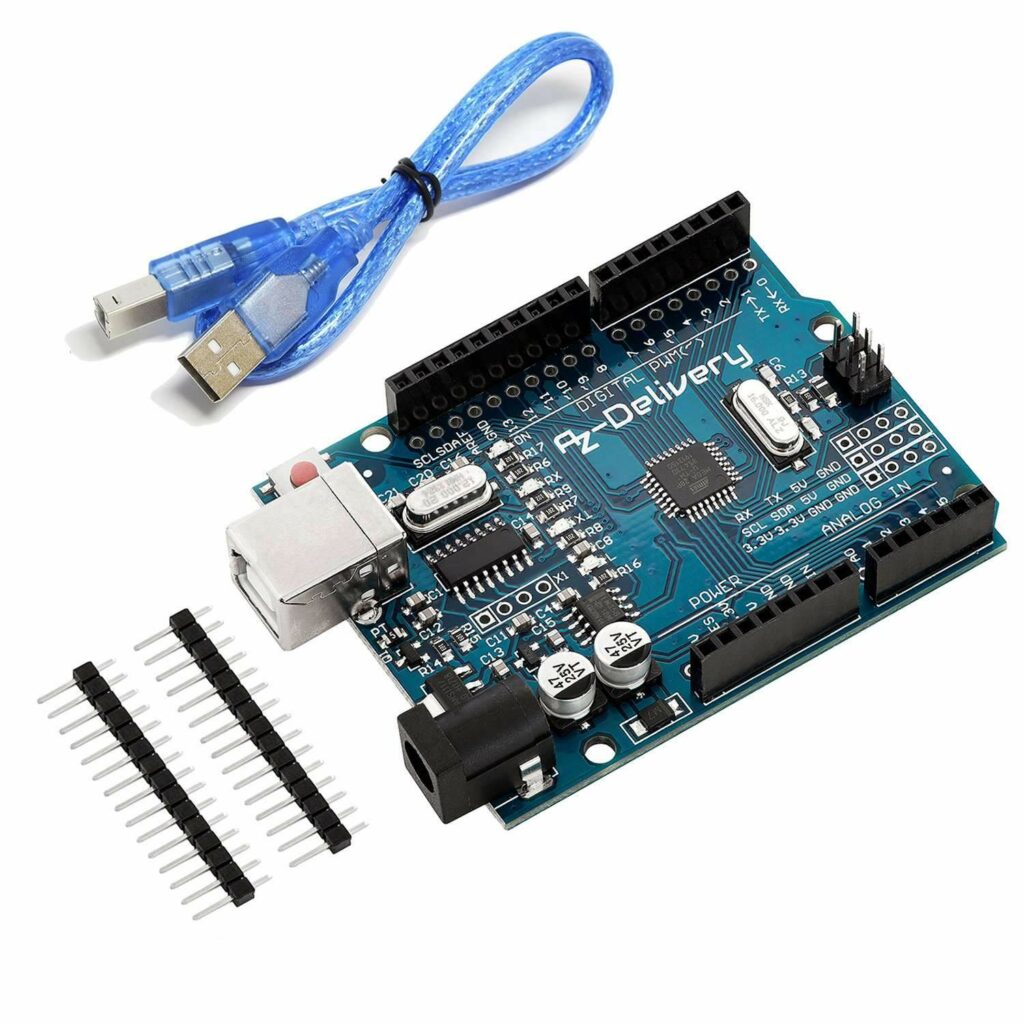

- Micro Processor

A microcontroller is a small, integrated circuit that functions as the brain of embedded systems, containing a CPU, memory, and various peripherals, capable of executing programmed tasks and controlling electronic devices with precision and efficiency.

Selected part: Arduino UNO

- Motor Drivers

A stepper motor driver is a specialized electronic component that controls the motion of a stepper motor by converting digital signals into precise steps and direction movements.

Selected part:

- PSU (Power Supply Unit)

A PSU, or Power Supply Unit, is an essential electronic device that converts mains voltage into stable and regulated power outputs, providing the necessary electrical energy to various components of a computer or electronic system.

Selected parts:

- Mean Well UHP-350 | 12V @ 30A – passive cooling – Tool & uC

- Mean Well UHP-750 | 24V @ 30A – passive cooling – Stepper motors

Official Website: meanwell.com

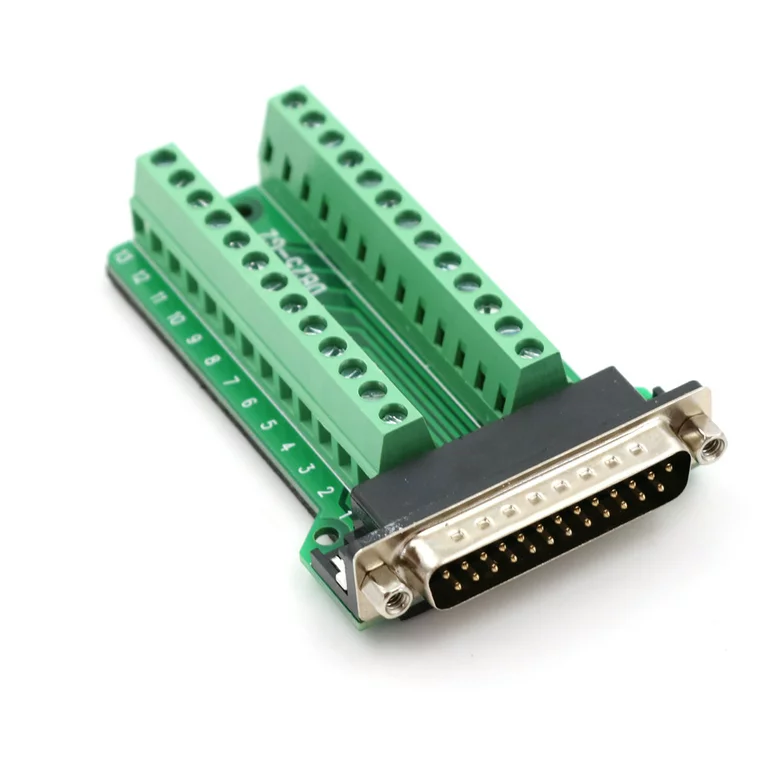

- I/O Ports

I/O ports, short for Input/Output ports, are hardware interfaces on a computer or electronic device that enable the exchange of data and signals with external peripherals, allowing for communication and interaction between the system and the outside world.

Selected parts:

- BD25 – 25 pin Paralell connector

- GX16 – 2 / 4 / 7 pinconnectors

- USB Type B

- Firmware

Firmware is a type of software specifically designed to be permanently embedded in electronic devices, providing essential instructions and control algorithms that enable the device to operate and perform its intended functions.

Selected Firmware:

GRBL (pronounced as “grubble”) is an open-source, highly popular, and widely used firmware designed specifically for controlling CNC (Computer Numerical Control) machines. It is known for its simplicity, efficiency, and compatibility with various hardware platforms. The name “GRBL” originally stood for “G-code Real-time Boot Loader,” but over time, it has become synonymous with the entire CNC control firmware.

While GRBL is well-suited for small-scale CNC machines, it may not be ideal for more complex industrial CNC applications that require advanced features, multi-axis control, or high-speed machining capabilities. For such applications, other commercial or proprietary CNC control software or firmware may be more appropriate. However, for hobbyists and DIY enthusiasts, GRBL remains a popular and accessible choice for controlling their CNC machines.

Official GitHub page: https://github.com/grbl/grbl